Evaluate the Efficiency of Machines for Mechanized Rail Line Infrastructure

Mohammad Heydari1 * , Bijan Alizadeh2 , R. Bahrami Yarahmadi3 and Sohail Ghiasvand4

1

Department of Civil Engineering,

Technical University of Lorestan Dorud,

Iran

2

Director General of Railways Lorestan,

3

Technical Assistant railway infrastructure in Lorestan,

4

Mdyramvzsh and research and technical structures Iran railway line,

Corresponding author Email: ali_heidari38@yahoo.com

DOI: http://dx.doi.org/10.12944/CWE.10.Special-Issue1.127

Existing railway lines in Iran is several years old, in combination with increased traffic lanes (tonnage and speed) line depreciation also increased with time left. Dlza basic repairs and maintenance of railway lines annually and is of great importance. In this regard, human resource professionals, specialized machinery, materials, and especially the specific maintenance and repairs, is of particular interest. The ballast layer of maintenance, tamping is considered as the most important. Factors affecting the tamping process ballast, the cost can be significantly reduced and the maximum operation time and the quality achieved. In this paper we describe the tamping operations, increase the efficiency of the factors affecting the efficiency of the review process ultimately results in the form of technical recommendations for increasing the efficiency of ballast tamping operation is provided.

Copy the following to cite this article:

Heydari M, Alizadeh B, Yarahmadi R. B, Ghiasvand S.Evaluate the Efficiency of Machines for Mechanized Rail Line Infrastructure. Special Issue of Curr World Environ 2015;10(Special Issue May 2015). DOI:http://dx.doi.org/10.12944/CWE.10.Special-Issue1.127

Copy the following to cite this URL:

Heydari M, Alizadeh B, Yarahmadi R. B, Ghiasvand S.Evaluate the Efficiency of Machines for Mechanized Rail Line Infrastructure. Special Issue of Curr World Environ 2015;10(Special Issue May 2015). Available from: http://www.cwejournal.org/?p=11575

Download article (pdf)

Citation Manager

Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2015-01-16 |

|---|---|

| Accepted: | 2015-02-11 |

Introduction

The railway sector, an important part of the transportation system is one of the country, And plays an essential role in the development of different regions of the country, which depends on the volume of freight transport and transfer of goods between major cities, ports and industrial centers and transportation of passengers, especially in urban areas. The annual cost of railway construction and maintenance spend a lot of it A railway safety, including passenger comfort also depends on a complex interaction of various components of the load wheels with values of frequency and period of the past, much of the attention of the pavement along (Traverses, and the rail fastenings) the path less infrastructure components that include high Zyrbalast and the substrate. The annual cost of railway construction and maintenance spend a lot of it. A railway safety, including passenger comfort also depends on a complex interaction of various components of the load wheels with values of frequency and period of the past, much of the attention of the pavement along (Traverses, and the rail fastenings) the. And considerations were less components, including the ballast road infrastructure, and the bed is under ballast .

Specifications and Public Ballast

layer ballast the main difference between high and high rail line, In this regard, several factors can affect the role of the structural layer which ballast mainly technical specifications and materials used in the general area. For example, Grading ballast materials, The mechanical strength of the material, especially in the face, smashing and grinding process, aggregate materials and chemical compounds that are formed on one side and thick, shoulder width and slope of the gable sides of layer ballast the other the most common problem is that in this context it refers. Due to the location of the railway ballast material, this layer is divided into different parts, which include:Shoulder ballast ;part of the material that ballast embedded in the ends of the sleepers and shoulder width and slope of the roof of the parties in this section apply. ballast between the traverses (feed box) ballast part of the material is placed between two sleepers during the tamping machine Tamping Machine is the cornerstone of the penetration depth. ballast and low: Part of the material ballast ballast the upper layers and layer under ballast (if any) are and tamping operations, pickaxes Tamping Machine tools are able to create congestion in the area. Usually this part ballast exposed to pollution from crushed seeds, ground into fine particles in the high ... And generally the weakest part of the layer ballast formed. In some railway authorities, ballast considered to be underbalast bottom of the layer [2] (Fig. 1) of the ballast layer and other layers in the rail.

![Figure 1: Part of the railway ballast layer and other layers [1]](http://www.cwejournal.org/wp-content/uploads/2015/06/Vol10_Spe_Eval_Mohd_Fig1-150x150.jpg) |

Figure1: Part of the railway ballast layer and other layers [1] Click here to View figure |

Duties of the Ballast Layer

The main functions ballast as follows [3]

- Forces stand upright, horizontal and lateral ties to hold the line against their specific situation

- Providing a portion of the resilient and energy absorption line

- Broadcast and transmission over the lower layers

- Surface water drainage

- Adjust the level of the rails during track laying and maintenance

- Damping and depreciation shocks, vibrations and sounds of movement of rail vehicles

- Frost insulation layer below

- Inhibit the growth of plants in the

Materials Suitable for Ballast

Layers of ballast quality materials used depends on the type and density of them. ballast materials to do their jobs with the following characteristics [3]

- Resistant to abrasion, are small and compaction.

- Resistant to atmospheric effects, with sufficient strength and have a uniform structure.

- Cubic possible to have sharp edges. In other words, the kind of rocks are broken.

- Due to the characteristics outlined ballast should igneous materials or blast furnace slag (without sulfur and phosphorus) is selected.

A good ballast should have the following characteristics:

- Resistance: ballast to the comminution of the fracture strength of the applied loads.

- Hardness: In addition to ballast hardness, resistance to breakage and not brittle.

- Durability, abrasion resistance and weathering durability is included.

- Durability, abrasion resistance and weathering durability is included.

- Stability: ballast to maintain its stability. Rounded grains of sand or gravel that all sand and clay materials to be separated, Not stable under load and on Ghltnd together. Granular structure and materials which are difficult and uncertain or irregular aggregation of sufficient materials are more stable.

- Drainage capacity: ballast well to allow rapid infiltration of surface water provided.

- Cleaning capabilities: a fine ballast to be capable of being cleaned manually or preferably by mechanical devices are available.

Availability of materials as possible near the site in order to not increase the costs of transport and equipment.

Failure Ballast

Component failure group is divided ballast into the following categories [3]:

- Fragmentation ballast: major cause of infection is ballast and the effect of various factorssuch as displacement, thermal stresses, freezing, chemical erosion, tamping, traffic and congestion occurs.

- The gradual penetration of high-level part in it, and it ballast delivered along with the other part Bvrqtar by factors such as wind, water and sky pollution occurs .

- Seeps of under ballast: The main reason for the shift ballast due to the layer of grain size is inappropriate, especially in humid conditions.

- Seeps from the seabed: the main reason for the erosion of hard fine clay particles from the stresses of high ac Zyrbalast and the presence of water. This can cause the pump to the clay slurry is caused by passing traffic.

ballast pollution: pollution ballast the origin of the various defects such as geometric imperfections in the rail line. So ballast the need for a replacement or screening should be. Causes of pollution can be divided into 5 main categories (Figure 2) [3].

|

Figure2: An example of failure ballast. Click here to View figure |

Plant Growth

As a result of the growth of plants, including grass, weeds, bushes, trees and other natural coating occurs within a line. Plant growth outside shoulder of the road, is permitted and even, especially along the sides of the embankment slopes to prevent erosion and Crawler effective, However, the material must be controlled in-line inspection or trains barrier not. Any plant growth around the shoulders and the constructions considered redundant and could lead to a weakening of the structure (Fig.3).

|

Figure3: An example of the failure Plant growth |

Insufficient and Shoulders Ballast the Line

The lack of shoulder ballast or ballast between the sleepers may be due to inaccuracies in the construction or renovation occurs. Shoulder ballast may be removed or due to construction, renovation, or other activities to reduce adjacent line. The cornice height of the bridge due to insufficient sometimes ran ballast and reduce the height of the bridge can be seen ballast the shoulder line. These factors will undermine the stability of the lateral line (Fig. 4).

|

Figure4: ballast at the shoulder and the inadequacy |

Poor drainage edge line: Poor drainage edge line: limit or prevent the flow of water in the direction parallel to the drains, canals or failure of this group are the side slopes. Flow may be blocked due to the growth of vegetation, debris, sediment, soil or other materials is limited or prevented. Excess water flow in drainage channels at high speeds can cause damage (Figure 5)

|

Figure5: sides improper drainage line |

The Ballast Tamping Process

The maintenance activities associated with the tamping ballast layer. That the lifting rail, ballast amended by adding the following geometry in the transverse direction and traverse to modify the geometry in the vertical direction. Tamping operation is usually done by machine Tamping Machine and pick those that are vibrating motion [3] (Figure 6) shows a view of a typical machine Tamping Machine.

|

Figure6: car Tamping Machine |

Mmhmtryn tamping the reasons are as follows:

- To achieve the level of geometric design (target) Railways

- Modification of geometric defects (the position

- equal density score in both the track and increase cargo capacity in order to improve the load distribution on several traverses property

- Align the side-line stability before the rapid deterioration and irreversible geometric lines and its constituent parts

Although ballast tamping operation is a modified line, but usually also has the following weaknesses:

- weakening effect collide in the context of its dense

- Reduce the possibility of buckling resistance and the side rails

- breach of the particles is high

Among the factors mentioned in the first two cases, a short time after the operation of the line to be corrected. But about a third of the ballast pollution increases, thereby increasing the on-line meeting, Especially when the line is exposed to rain or groundwater Seeps, preventing proper drainage and increased line speeds session. Tamping process generally involves the following operations:

Traversing Ballast Density Below

Tamping Machine devices are available to help pick. So that with the help of special clamps, two rails to be pulled up to a certain size, And then pick ballast the device with a vibration frequency 35HZ layer ballast depressed and the track is compressed.

Modify Crowbar

Jimmy eat due to the geometric horizontal line with a the general a movement of the rails and traverse of the line are. This defect causes the loss of the smooth motion and the forces exerted on the line can be increased, resulting in a faster decline line will follow.Tamping Machine tools for measuring and determining the correct axis and the applied force, the rails are put in place And this does not solve the problem.

Modify the Lateral Line

In particular, the lines that traverse the width of the wood and metal, occurs, so that the lateral forces exerted by one of the rails out of place exactly,And thus the width of the line increases. Tamping Machine passing car, the rails are returned to their exact location.

Set the Shift Length

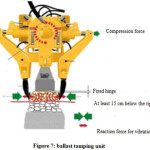

The line width of the arc flash occurs. So that the exact track of lateral forces from their original positions outside the arc. The flaw in manually or by using a camera with a drawstring at the state track meet is Tamping Machine passing car, Figure (7), for each rail tamping unit attached to the main body (chassis Mobil), which is equipped with Slyndr for raising and lowering there. Tamping unit includes (the blade or aging) and a vibrator motor (hydraulic motor) and a flywheel is centrifugal. Two independent tamping unit for each rail is provided through the vertical column guides to frame or chassis Mobil machine connected.

Tamping unit for tamping each track provides the arrangement found in pairs and each pair of traversing through 8 on each side of the rail tampinTamping unit on a horizontal column to move the party to carry out the automatic detection of the curve makes it possible. Blades with pistons that are hinged on an eccentric axle, hydraulic engine is vibrating.

|

Figure7: ballast tamping unit Click here to View figure |

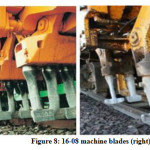

As noted for each side sleepers, tamping arm 16 is used. For multiple tie tamping, the unit is equipped with 32 arms (picks) (for the track) is used. Figure 8, the car is also Yrasas number of blades is 16, indicating that the blade 16 is enough for a tie, "32" is for two sleepers. Tamping unit for tamping machine Yvnymt an additional drop arm and needle are intersections. Special unit for electric lines with the third rail is used.

|

Figure8: 16-08 machine blades (right) and 32-09 (left( |

Factors Affecting the Efficiency of Operations Tamping Machine

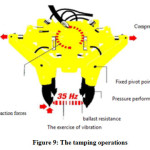

The main factors affecting the efficiency of the ballast tamping operations include: frequency, amplitude (magnitude), pressure and time (0.8 to 12 seconds), the rate of pressure by tamping unit ,The vertical line level rise and increases in the frequency of 35 Hz is generated. The behavior of elastic - plastic high altitude reduces the level traversing at high frequencies are done.ballast moving at low frequencies is limited to a considerable extent. Not only a force, but also a certain time ballast needed to rearrange grains. The actual density of energy during tamping operations through a short half sine wave positive impact on congestion by moving the top picks are applied Tamping Machine.

In order to achieve the ballast quality compression tamping traverse the line of considerable practical importance is enjoyed. In case of insufficient depth, tamping picks are treated as if deep traverse, concrete traverse under a uniform and dense is insufficient. The optimal range of the tamping machine tamping the new electronically controlled carefully placed in millimeters. Tamping balancing effect on the rate of decline and the most appropriate structure makes the form (9) View of the ballast tamping operation shows.

|

Figure9: The tamping operations Click here to View figure |

Optimal vibration frequency of 35 Hz is tamping page placement. The maximum values of density and geometric contour line on the frequency stability is achieved. Figure (10), at frequencies greater than 35 Hz "liquefaction" ballast caused by the lack of ballast-density granular layer will follow. At a frequency of 40 Hz ballast grain of the screen moves to escape the tamping picks.

|

Figure10: Liquefaction ballast frequencies over 40 Hz Click here to View figure |

The optimal duration of exercise at least 5 milliseconds to shift and change the arrangement of seeds is ballast. The frequency of ballast density, the frequencies around 35 Hz tamping is necessary. At frequencies higher compression rate to rise to high levels of congestion along enough kick, ensure. However, due to ballast resistance, the increase should only be done to a limited extent. The maximum sustainable level of geometric line of ballast-density granular layer (minimum deformation) is obtainable only at a frequency of 35 Hz..

|

Figure11: deformed under dynamic loads |

Figure (11), power is transmitted at a frequency of 35 Hz, 45 Hz frequency is about twice the corresponding energy.Vibration control is similar to that of tamping unit during operation of the differential pressure is generated, is able to create a high density of grains and grain compressibility is as can be increased. will follow.

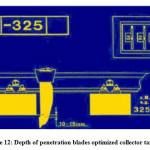

Improving the Operation of the Ballast Tamping

Train loaded, the ballast particles are gradually eats conference line is heterogeneous. Tamping operation to restore the geometric position of the line is correct and to ensure the safety and comfort of travel takes place. During the tamping operation, the influence of vibration pick at the edges of the particles ballast ballast causing a fracture which produces smaller particles. On the other hand, traffic levels are ballast the grit particles that are thus transformed into particles with a smooth surface. In the long run, when the space between the particles of the fine particles, leading to a gradual loss Alastyssth and drainage properties are ballast. ballast angular particles accelerates the degradation of the next meeting, because the particles are round the corner lock becomes less effective. Figure (12), designed to provide the optimum accumulation ballast necessary in traverse the collector blades penetrate to a depth of 15-20 mm below the traverse ,If the blade is small troughs, and ran ballast the blade, resulting in the accumulation of non-uniform flow under the traverse. Following the investigation, some technical and practical suggestions for improving the operation of tamping ballast tamping before and during the study and presented.

|

Figure12: Depth of penetration blades optimized collector tamping unit |

Necessary Steps Before Tamping Operations

traverse are broken and worn should be replaced. Why the change traverse after tamping operation will cause disharmony line. In other words, the number of traverses tamping done under some do not..

- Ties are broken and worn should be replaced. Why the change traversing after tamping operation will cause disharmony line. In other words, the number of sleepers tamping done under some do not..

- Line width should be set, misalignment and change the line width impairs the crowbar work.

- Complexity and potential curl on rails must be resolved, because the tamping machine is not able to eliminate these disadvantages.

- Effective and reliable means for tamping, you can pick up in the region of the stacking machine.

- Woman packing operations and joint spacing should be adjusted and, if possible pressure on the line, the pressure is relieved. In this regard, any action after the car backfire on-line maintenance, as well as the train comes.

- The radius of curvature should be set. As previously mentioned, the range of the longitudinal profile must be specified. Because the machine is not able to change the arc radius.

- Drainage lines should be done while tamping.

- Waste, scrap metal coarse stone ballast should be separated, because they are able to pick up the pieces are pressed and not paying attention to this problem is not uniform koobideh below traversing

- Bolts and fastenings must be strong because tamping machine, rail when leveling up his bed

- Barrier local level, should guide rails on the sides of the rails have been removed, and underlined is thrown because the machine is able to work in these areas.

- The unchanging such as: balance bridge, the beginning and end of linkage curves, arches, turns and outer rails must be marked before

What Collector pressure that typically 115 to 125 times the line for repairs and new installations should be 95 to 110 times

Time for collectors - is the optimum time of 0.8 seconds (1.2 seconds for the new line installation and repair

Tamping depth - the depth should be optimized so that the tip of the blade between 15 - 20 mm below the traverse line for greater stability, tamping unit and collector should be set as follows:

Tamping Machine Tool depth should be set height rail sleepers + height + rubber pad

Tamping Machine vibration unit pressure: 150 BAR

Size = 70 * 140mm blades picks

Minimum cumulative high = 150mm

= 0.4 to 0.6 seconds in the time picker

Collector voltage according to the type of traverse:CST-9=90-100bar

Wood and metal = 100-110Bar

PRC=110-125bar

Pt& Xing Machine- UNI=150bar

Actions During Tamping

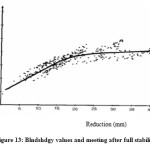

Tamping pick of the litter when it came to the size of the tamping tool is placed inside the bed. If Blndshdgy utilizes small amounts, may prevent or resist penetration by tamping picks in there bed..

|

Figure13: Blndshdgy values and meeting after full stabilization of the |

Figure (13), the relationship between the amounts of waste Blndshdgy Blndshdgy vertical line shows the balance. As you can easily figure (13) can also be picked up in less than 15 to 20 mm, no permanent modification of the species remains

However, if the amount Blndshdgy (for example) 40 mm is applied to geometric imperfections in the next round will be held only 20 mm and provided with time to take advantage of the values of "optimized" to increase the level of elevation, damage to their the completely out of line will be deleted.

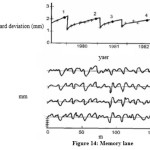

If you do not pay attention to this problem, the failure of the line are the so-called "memory" or "memory" line is known. This term refers to the phenomenon that the maintenance operations in a difficult position after his return before tamping operations ,Figure (14), a very short period of time between the tamping show that is very rare in European countries,But this example is adapted from the British Railways, the phenomenon of "the line" as a specific show. In order to achieve the fulcrum traversing dense, high seed in the traversing horizontally compresses, while the load is applied along the vertical rail. High grain loading operation during the first period (0.5 to 2 million net) change flourish and it continues until reaching a stable level geometry. Geometrically stable level is determined by a balance in which transmission paths between the grains are high enough to transfer vertical loads to lower soil there. In the first period stablizers line, exponential behavior pattern session will be very fast.

The idea too Blndshdgy predicted values of the control over the design values, due to the increased level of vertical lines of the design (zero) in areas where large amounts of meeting the expected level so long the loading operation comes from meeting the desired mode.The advantage of this method is to obtain the longitudinal balance is very stable and durable.

|

Figure14: Memory lane |

Conclusion

Much of the annual development budget of all countries, regardless repair, improvement and maintenance of railway lines will be Spend the bulk of development credits made to reduce costs and manage them to allocate more serious topic. Because this cuts or spending, staying in top management of the organization in charge of the construction and maintenance of financial challenges, role plays ,In this paper, we introduce a ballast tamping process, its advantages and disadvantages described. Finally, the most important factors affecting the efficiency of the ballast tamping ballast tamping mention Impact each process efficiency were discussed. The main results can be summarized as follows Optimal operation of tamping, 15 mm space between the seat traverse position and is Tamping Machine pickaxes Optimal vibration frequency of 35 Hz is tamping plate of pickaxes The bst values of the density and the highest level of geometric lines of the frequency stability is achieved. The frequency of ballast density only at a frequency of 35 Hz to find tamping.. In this stud the frequencies around 35 Hz tamping is necessary.

In this study, the most important to the operation performed before and during tamping ballast tamping operations in terms of technical proposals were presented and applied in the rail transportation industry.

References

- Department of Planning and Strategic Supervision presidential, 2008, Publication 355, Guidelines for monitoring the implementation of high speed railway superstructure

- Mir Mohammad Sadeghi, J. et al, 2010, the principles of analysis and design of high rail lines, University of Science and Technology

- Mavnt Presidential strategic planning and oversight, 2007, Publication 355, Guidelines for monitoring the implementation of the road pavement

- vice presidential strategic planning and oversight, 2006, Publication 301, Standard Specification for railway ballast superstructure

- Nsrazdany, M., et al., 2006, high material and its impact on the maintenance of railway lines, National Maintenance Conference.